Dispatch miners, their equipment, and expensive tools with all the information and confidence you need by using View360 AI to create a trustworthy source of truth that streamlines your mining operations.

Drive business agility and sustainability with View360. Leverage AI-infused solutions for field management, asset management, and process automation to reduce operational costs and increase worker safety.

Build an orchestrated ecosystem on the View360s platform with intelligent automation and native integrations with your existing technology stack for real-time data insights. Our no-code platform helps you build and customize processes and workflows in an easy drag-and-drag interface.

Data suggests that 50 percent of mining companies have already invested in IIoT integration, and the rest are planning to invest in the next few years. IIoT adoption is the new essential for all mining and industrial organizations to gain prescriptive and preventive insights from data collected with IIoT-enabled equipment and assets. View360's AI and ML-powered platform can use all the data to build data models and cognitive insights for key insights in decision-making and process automation triggers.

The industrial industry has considered workforce safety as their top priority for many years now and constantly looking to connect their workforce with the latest industry best practices. There are several smart devices, sensors, smart wearable gear for workers to monitor and track their activities in real time to avert any possible accidents at work sites. Connected smart devices and smart wearables help monitor fatigue and cognitive impairment levels to enhance worker safety along with operational improvement possibilities like smart scheduling route optimization with real-time GPS tracking of workers.

Leverage the View360 platform to build a digital twin of all your IIoT-connected assets to get predictive and prescriptive maintenance insights to avoid unplanned downtime. Configure customized alerts for timely repair or replacement of assets to avoid equipment failure and production issues. Data collected from all the assets can make a huge data lake that can be utilized to build data models that can provide key insights to operators for automated processes, triggers, and timely action.

Connect your people, equipment, and technology through IoT integration to enable operational excellence across the organization. Gain from predictive asset health analytics to prevent equipment failure and unexpected downtime.

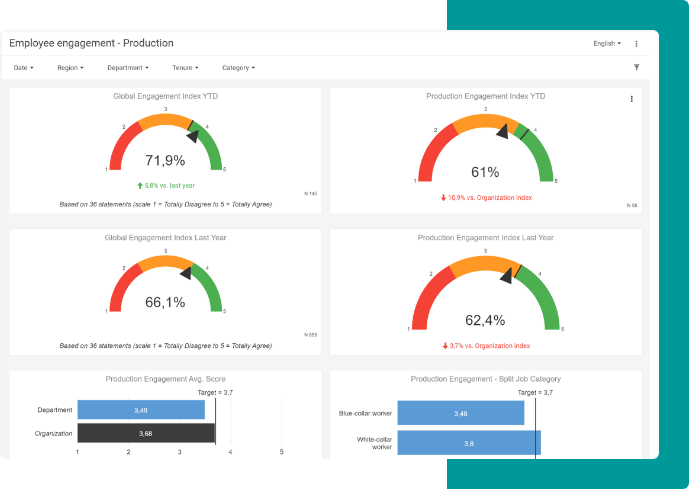

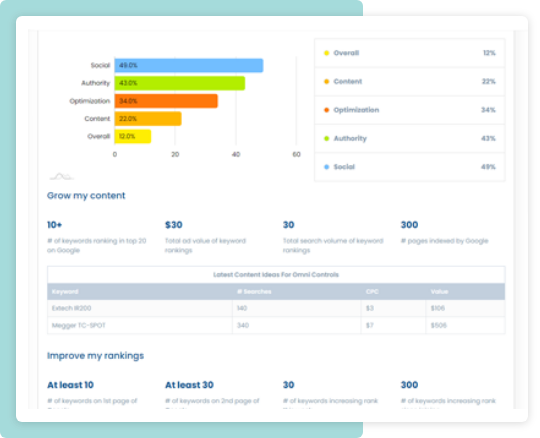

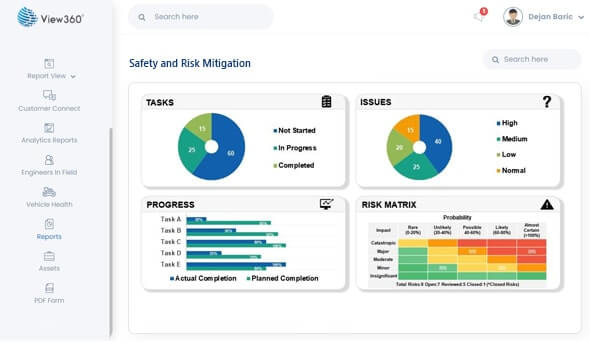

Automate your business and production processes to get real-time data insights for operational efficiency and immediate action in critical situations. Configure role-based customized dashboards to keep track of key metrics and actionable insights.

Bring the value of data to make key decisions. View360 platform can help break silos, and enable easy data pull from your legacy systems for key data insights on an integrated no-code platform. Create reports and data visualizations with an easy drag-and-drop interface.

Track and monitor worker condition in real time to measure fatigue and cognitive impairment levels. Install sensors on worker gear and a worker safety app on their connected devices to monitor real-time status to avert potential accidents.

This is our story of co-creating a solution with a Global Non-vessel Operating Common Carrier (NVOCC)

Any international shipping and logistics process has multiple challenges. Key among them is managing the significant amount of information that changes hands continuously during the process.

Often, the processes are decentralized and manual in nature. Further, global operations require dealing with different legal requirements and local variances. Hence, consolidating and centralizing the operations while maintaining the country-specific nuances is a complex task. It also calls for a deep understanding of the shipping and logistics industry, underpinned by digital and automation capabilities, to standardize the operations and ensure on-time delivery, high accuracy, and low costs.

It had acquired several shipping and logistics companies across the globe, including those in Italy, Brazil, France, and the U.S. Each acquired company had its own technology, process methodology, and customer and country-specific nuances. The client thus had diverse systems and processes and no uniform view of the entire operations. Decentralized, non-standardized, and manual processes across 60 countries have led to high operations costs, increased Turnaround Time (TAT), and errors.

The client required a solution that entailed consolidating and standardizing the operations, while maintaining the customer and country-specific nuances. A global operating model that included process excellence, digitization and automation had to be deployed to bring down costs and eliminate errors.

Increased Worker Safety

Connected Mining Data and Information Flows

Improved Profitability

Our client is a supplier of equipment and tools, services, and technical solutions for mining and mine construction industries in the United States. They specialize in providing their client with tools for processes such as rock drilling, rock cutting, crushing and screening, loading and hauling, tunneling, quarrying, breaking, and demolition

The client wanted a modern infrastructure solution that would allow them to -

Ensure safety measures to minimize business risk by increasing your safety policy effectiveness. Transform and digitize processes, controls, and assets and bring transparency to your workforce.

Earlier, our analysts had to create visualization routes and parse Epik Solutions, which provided us with a highly creative IT solution that helped us bring transparency to our processes, minimize the human errors caused by delivering our products, and develop a novel customer engagement strategy while boosting our company revenue.